Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: FT63/FT75/FT95

Brand: SHANDONG LIGHT

Applicable Industry: Manufacturing Plant, Food &Amp; Beverage Factory

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc, Engine, Bearing, Gearbox, Motor, Pressure Vessel, Gear, Pump

Old And New: New

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: High Productivity

Capacity:: 100-1000kg Per Hour As Optional

Model: Lt70-L/Ft63/Ft75/Ft95

Motor: Siemens/Abb Can Customzied

Electric Parts: Abb,Siemens,Omron,Delta

Machinery Materials: Stainless Steel

Automation: Fully Automatic

Raw Materials: Broken Rice/Rice Powder

Control: Plc Control

Features: High Efficiency

Product Name: Nutrition/Fortified/Enriched Rice Machine

Packaging: Wooden case or packing film Strong Fumigation-Free Plywood Cases or 20' GP or 40' HQ

Productivity: 100-1000kg per hour

Transportation: Ocean

Place of Origin: CHINA

Supply Ability: 30 sets per Month

Certificate: CE ISO9000

HS Code: 84388000

Port: QINGDAO

Payment Type: L/C,T/T,D/P,D/A,Paypal,Others

Incoterm: FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP,DDU,DAF,DES

Enriched Artificial Fortified Nutritional Rice Plant Making Manufacturing Processing Machine

Introduction:

Enriched Artificial Fortified Nutritional Rice Plant Making Manufacturing Processing Machine is studied in concern with the loss of nutritional elements in the rice which is made by the traditional rice processing. Rice and its by-products can be produced into high nutritional foods by adding additional nutrient components before extrusion cooking. Further, by this process, the broken rice and rice bran can be reused. Process for making artificial rice grains, comprises mixing rice flour, water and oil and cooking them in extruder, forming into rice-grain shape, drying and cooling in low temperature. The technique makes it feasible to avoid the loss of nutrition.

The production of fortified rice offers the unique possibilitu to efficiently rice with multiple micronuntrients. Vitamins and minerals such as vitaminn A and B family as well as iron and zinc can be chosen for inciusion.

Different Model with capacity of Instant rice making machine:

Process Flow chart:

FROM LEFT TO RIGHT:

MATERIALS MIXING SYSTEM → EXTRUSION SYSTEM → VIBRANT COOLER → DRYING SYSTEM → COOLING SYSTEM

MATERIALS MIXING SYSTEM Working Principle VIBRANT COOLER EXTRUSION SYSTEM DRYING SYSTEM Working Principle COOLING SYSTEM Working Principle

conmbustion system, dehumidifier system, sheet metal insulation system and controlling system.

and available for packing.

Sample Shown:

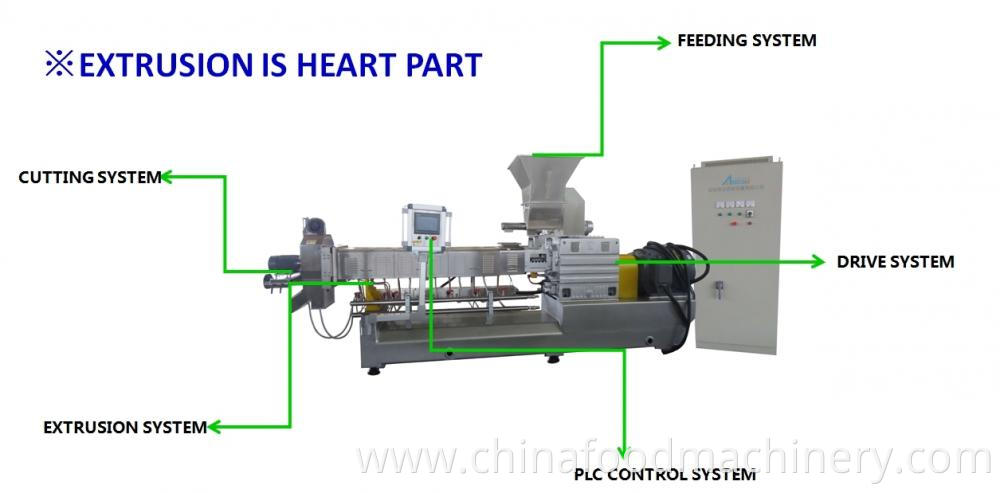

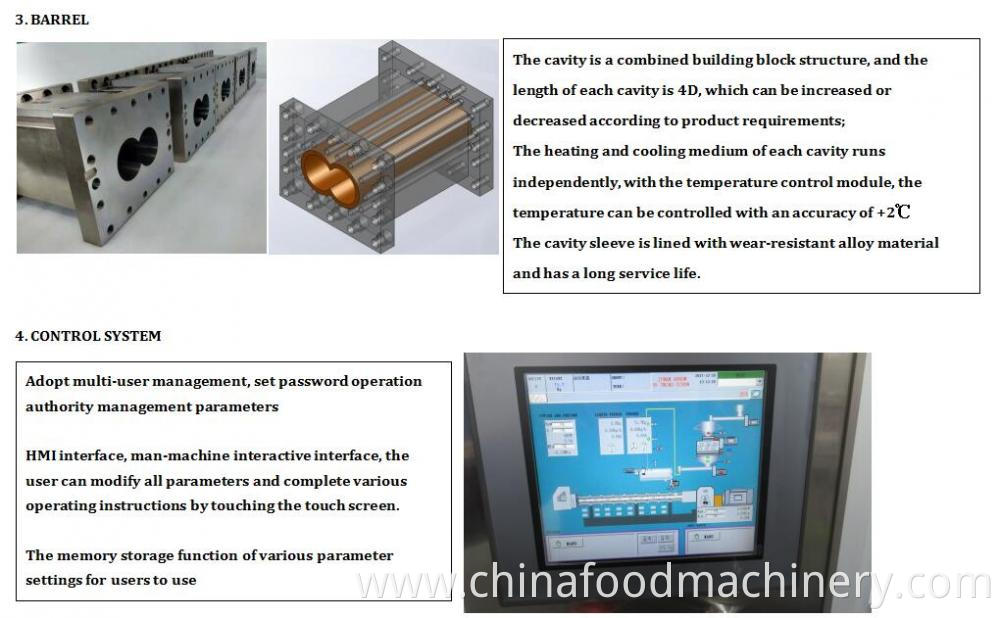

Our Extruder Advantages:

CO-Cooperation case

FACTORY INTRODUCTION

Product Categories : Instant Food Production Solution > Instant Fortified Rice Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.